Engineered Wood Products

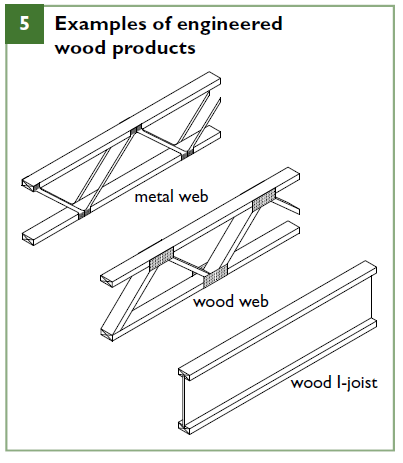

Several types of engineered wood products (EWPs) are routinely used in wood-frame house construction. These products can provide equivalent or superior strength compared with dimension lumber and are typically manufactured using less wood fibre and available in long lengths. They include: wood I-joists, glulam, plywood, oriented strand board (OSB), laminated veneer lumber (LVL) and others. Dimension lumber and other wood products are often combined in the manufacture of EWPs using glue or mechanical fasteners (for example, prefabricated trusses). See Figure 5. Wood I-joists consist of lumber or LVL flanges and OSB webs.

Figure 5

All these products provide design flexibility by virtue of their longer span capabilities and higher strength compared to dimension lumber.

Structural composite lumber (SCL) includes laminated veneer lumber (LVL), parallel-strand lumber (PSL), laminated strand lumber (LSL) and oriented strand lumber (OSL).

Laminated veneer lumber consists of thin veneer panels laid parallel to the longitudinal direction, coated with a waterproof adhesive, and bonded by heat and pressure. Available in a wide variety of sizes and strengths, LVL may be cut into desired lengths for use as beams, columns, headers (lintels), joists and as flanges for wood I-joists.

Parallel-strand lumber is manufactured using thin veneer panels cut into narrow strips and

then bonded together using a process similar to LVL. Members are available in a variety of

widths, depths and lengths, and are primarily used as beams, columns and headers.

Laminated strand lumber and oriented strand lumber are manufactured using wood strands combined with an adhesive and are oriented and formed into a large mat and pressed. LSL and OSL are commonly used as beams, headers and studs.

Source : Canada Mortgage and Housing Corporation (CMHC)