Valley Flashing

(1) Where sloping surfaces of shingled roofs intersect to form a valley, the valley shall be flashed.

(2) Valley flashing shall be installed over continuous sheathing.

(3) Closed valleys shall not be used with rigid shingles on slopes of less than 1 in 1.2.

(4) Closed valley flashing shall consist of sheet metal, self sealing composite membranes consisting of polyethylene and bituminous material or one layer of either Type S smooth surface roll roofing or Type M mineral surface roll roofing (mineral surface down) not less than 600 mm wide, and nails shall not penetrate the flashing within 75 mm of its edge or 124 mm of the bottom of the valley centreline.

(5) Open valleys shall be flashed with,

(a) at least one layer of sheet metal not less than 600 mm wide, or

(b) no fewer than two layers of roll roofing.

(6) The bottom layer of roofing required in Sentence (4) shall consist of not less than Type S smooth roll roofing or Type M mineral surface roll roofing (mineral surface down) not less than 457 mm wide, centred in the valley and fastened with nails spaced not more than 450 mm o.c. located 25 mm away from the edges.

(7) The top layer of roofing required in Sentence (4) shall consist of not less than Type M mineral surface roll roofing (mineral surface up), 914 mm wide, centred in the valley, applied over a 100 mm wide strip of cement along each edge of the bottom layer, and fastened with a sufficient number of nails to hold it in place until the shingles are applied.

Article 9.26.4.3. Ontario Regulation 332/12 Building Code, Information published by oncodes.ca for educational purposes only.

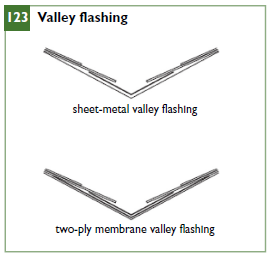

Valley flashing

A “valley flashing” should be installed where two roof slopes intersect to form a valley. Open valleys leave the middle of the flashing exposed (see Figure 123) and must be flashed with one layer of sheet metal at least 600 mm (24 in.) wide, or with two layers of roll roofing installed over continuous sheathing. The bottom layer is Type S smooth roll roofing or Type M mineral surface roofing (mineral surface down), at least 457 mm (18 in.) wide. Centre this layer on the valley and fasten along the edges with nails spaced 400 to 450 mm (16 to 18 in.) apart.

Apply a 100 mm (4 in.) band of roofing cement along the edge of the bottom layer. Then apply a second strip of Type M mineral surface roll roofing approximately 914 mm (36 in.) wide over the first layer (mineral surface up). Fasten the top layer along the edges with enough nails to hold it in place until the shingles are applied. The roof shingles stop 100 to 150 mm (4 to 6 in.) from the centre of the valley, with the distance increasing from top to bottom.

Closed valleys are usually flashed with one layer of sheet metal. Each course of shingles is continued across the valley to conceal the flashing. Shingle nails must not be placed within 75 mm (3 in.) of the valley centre line at the ridge, or within 125 mm (5 in.) at the eaves. Rigid shingles should not be used in closed valley roofs or roofs that slope less than 1:1.2.

Figure 123

Source : Canada Mortgage and Housing Corporation (CMHC)