Exterior doors, like windows, affect the appearance of a dwelling and are often selected on the basis of style and finish. Most manufactured exterior doors come as manufactured units pre-hung in their frames and ready for installation within a rough opening.

Exterior doors are usually manufactured of wood, steel, plastic or fibreglass. Wood doors are normally solid, while other types consist of inner and outer structural panels filled with insulation and are more energy-efficient. However, wood doors have proven performance and a traditional appearance that have contributed to their popularity.

Main doors should not be less than 45 mm (13⁄4 in.) thick. They should be at least 810 mm (32 in.) wide and 1.98 m (6 ft. 6 in.) high.

Nearly all doors are purchased and installed as complete manufactured systems (Figure 133). When custom doors are required, they must meet the same durability and performance requirements as manufactured units. In addition, some components may have to be milled prior to assembly and installation. Weatherstripping is the primary line of defence against air leakage around doors. It should fit tightly and be effective, durable and easy to replace. It is good practice for doors to be protected by overhangs to limit exposure to wetting. Exterior doors should be installed with the same attention to sealing and flashing as windows.

Figure 133

Doors that lead from the house to the garage must provide a gas-tight barrier to prevent automobile exhaust fumes from entering the house. These doors should be tight-fitting, weatherstripped and provided with a self-closing device.

Glazing

Glazing in exterior doors should be thermally efficient, and depending on their size and location, may also have to be tempered for added safety. Glass sidelights greater than 500 mm (20 in.) wide that could be mistaken for a door and glass in storm or sliding doors is required to be safety glass. Sidelights must be double-glazed. When no glazing is provided, a door viewer is required for security purposes. As is the case for windows, the amount of glazing in side doors near property lines may be restricted depending on the distance to the property line.

Resistance to Forced Entry

Hardware, in particular locksets and hinges, must be both functional and durable. The main entry door to a dwelling will be locked and unlocked, opened and closed numerous times over its useful life. Low-cost hardware will eventually need to be replaced and may cost more in the long run.

The Harmonized Standard and Canadian Supplement contain requirements pertaining to resistance to forced entry for door hardware. Manufactured and site-built doors must meet these requirements.

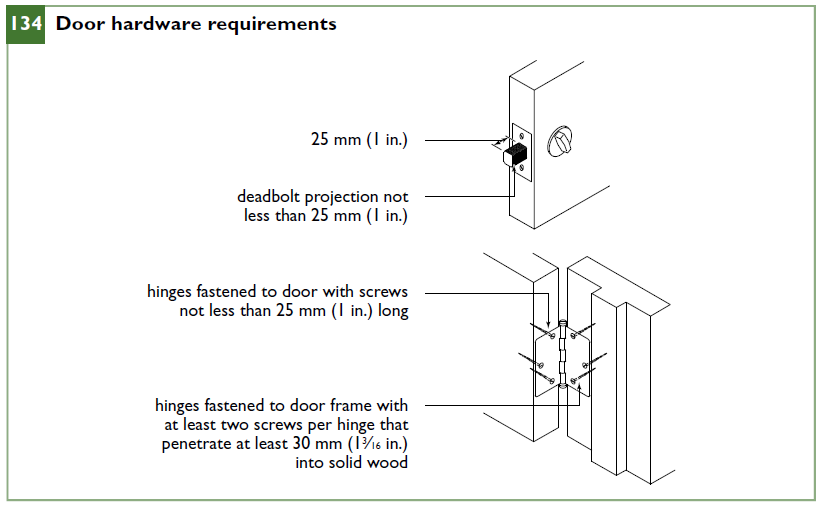

Deadbolt locks in exterior doors to houses must have a cylinder with no fewer than five pins and a bolt throw of at least 25 mm (1 in.) (Figure 134). Double doors must have heavy duty bolts top and bottom with an engagement of at least 15 mm (5⁄8 in.). Hinges must be fastened to wood doors with wood screws not less than 25 mm (1 in.) long, and to wood frames penetrating at least 30 mm (13⁄16 in.) into solid wood.

Resistance to forced entry extends beyond door hardware to the framing for the door as well. Solid blocking must be provided on both sides of the doorway at lock height between the jamb for the door and the structural framing so that the jambs resist spreading by force. Additional screws in the drywall around the doorframe will also strengthen resistance to forced entry. Doors conforming to the Harmonized Standard and Canadian Supplement meet these requirements.

Figure 134

Source : Canada Mortgage and Housing Corporation (CMHC)