Fireplaces

Fireplaces can consist of solid masonry construction, be factory-built, have steel inserts for masonry or wood frame construction, or be factory-built natural gas appliances. Special wood pellet burning appliances are available as well.

All fireplaces must be designed properly to provide heat, safely remove combustion by-products and not pose a fire hazard. Fireplaces should have an external air supply so that warm, room air is not used for combustion. A fireplace that is a solid-fuel-burning appliance requires that CO alarms be installed in living spaces, especially near bedrooms.

Masonry Fireplaces

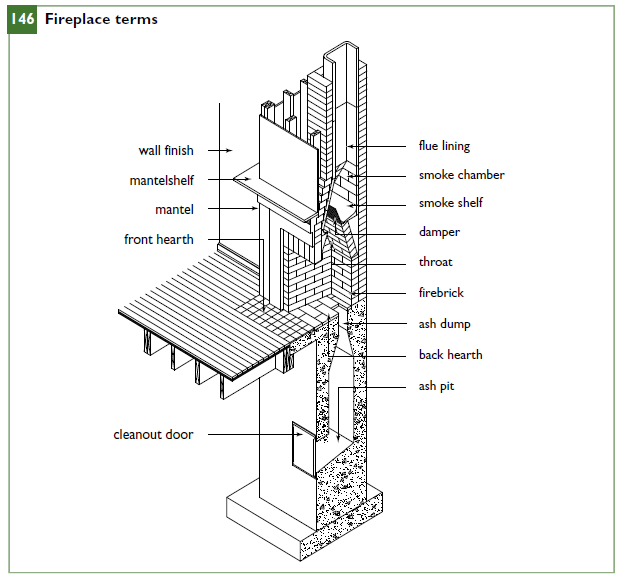

A conventional masonry fireplace has very low heating efficiency because it draws large amounts of room air up the flue that must be replaced by air leakage through the building envelope elsewhere in the house. This results in a warm room where the fireplace is located but a cold house elsewhere due to increased air leakage. Masonry fireplaces located on an exterior wall can be a significant source of conductive heat loss and air leakage through walls. The components of a masonry fireplace are shown in Figure 146.

It is convenient but not essential to have an ash dump through which ashes can be dropped into an ash pit with a cleanout door in the basement for periodic removal of ashes. Other design guidelines are:

The distance from the back of the fire chamber to the face of the fireplace cannot be less than 300 mm (12 in.);

- The front of the fire chamber should be wider than the back;

- The upper part of the back should tilt toward the face of the fireplace for better burning performance;

- The back, which should rise one half the height of the opening before sloping forward, should be about two thirds of the opening in width;

- Provide a smoke shelf to reduce backdrafts by projecting the throat toward the face of the fireplace.

- The throat should be as wide and as shallow as possible, but its area cannot be less than the area of the flue. The sides of the fireplace above the throat are drawn together to abut the flue over the centre of the width of the fireplace;

- The slope of the sides of the smoke chamber must not be more than 45° from the vertical: and

- Provide an adjustable damper to regulate the draft. It should be fully closable to minimize heat loss up the chimney when the fireplace is not in use

Figure 146

The lining of the fire chamber must be firebrick at least 50 mm (2 in.) thick and high temperature cement mortar or steel.

If a firebrick liner is used, the back and sides of the fireplace must be at least 190 mm (8 in.) thick including the thickness of the masonry liner. For a steel fireplace liner with an air circulating chamber surrounding the fire chamber, the back and sides may be solid masonry units at least 90 mm (31⁄2 in.) thick or hollow units at least 190 mm (8 in.).

The hearth may be even with or above the floor and consists of two parts: the front or finish hearth and the back hearth under the fire. The back hearth is built of firebrick as it must withstand more heat. The front hearth guards against flying sparks and is made of reinforced concrete at least 100 mm (4 in.) thick that is often finished with ceramic tile. The front hearth must extend at least 400 mm (16 in.) in front of the fireplace opening and at least 200 mm (8 in.) on each side. Provide a clearance of at least 100 mm (4 in.) between a fireplace and interior wood framing and at least 50 mm (2 in.) for wood framing at an exterior wall.

Source : Canada Mortgage and Housing Corporation (CMHC)