Window Installation

Windows are usually installed after the house framing and roof covering have been completed. Windows should arrive just in time for installation. If they are delivered early, store them upright in a secure, dry and level area in their original packaging with any temporary bracing left in place. Screens are susceptible to damage and should be removed, labelled and stored until construction is complete.

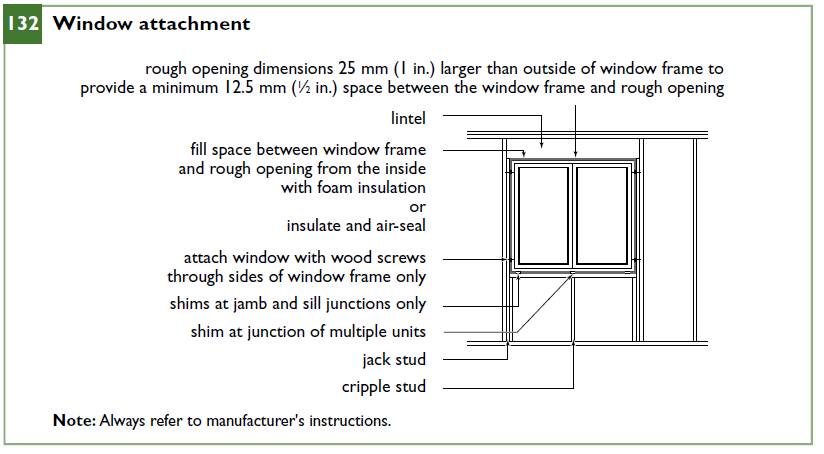

Prior to installation, review the manufacturer’s installation instructions, and ensure that all of the proper tools, fasteners and materials are available. Install windows plumb and level within the rough opening using shims to position and temporarily secure them.

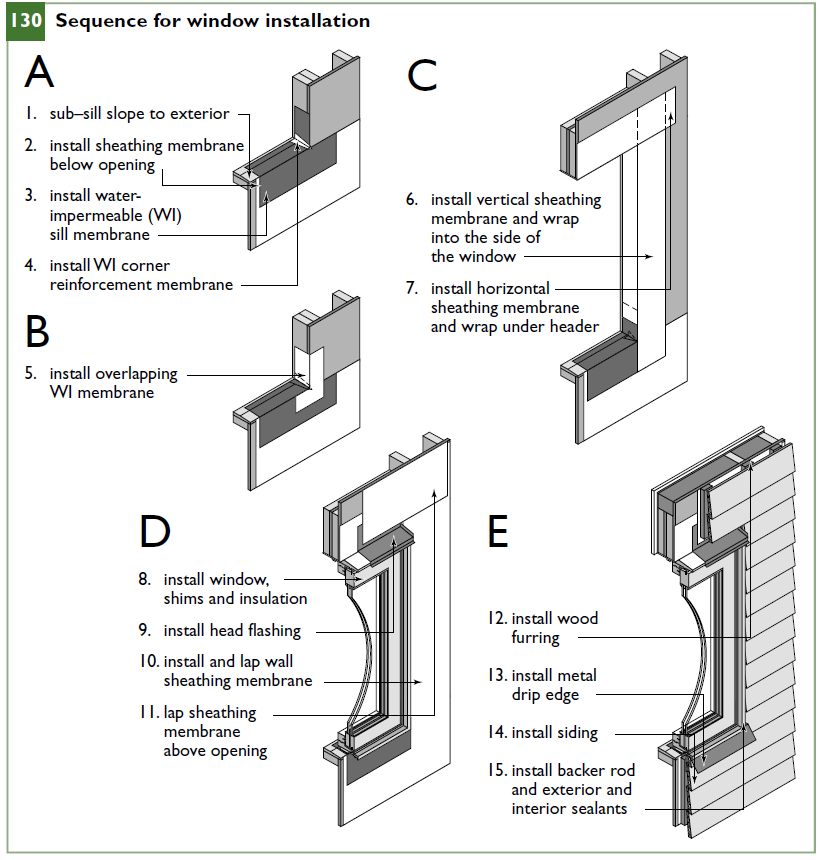

Improper window installation can result in water and air leakage problems and poor functioning of operable units. Correct window installation includes lapping and sealing the water-impermeable sheathing membrane to the window to form a continuous second plane of protection at the window perimeter, and in particular, provide drainage of the sub-sill area (Figure 130).

Depending on the technique used to insulate and air seal the window breaching (the gap between the window and the rough opening), air sealing may be performed after the window is installed. The most common technique now involves applying closed-cell sprayed foam to insulate and air seal the breaching in one step after the window is installed.

Figure 130

The window must be connected to appropriate materials in the adjacent wall construction to maintain the continuity of the first and second planes of protection as well as the air barrier. It is best to connect the air barrier at the interior edge of the window so that any incidental water leakage through the window can be readily drained to the exterior.

Although insulating around the frame in the rough opening can provide some thermal benefit, it does limit the drainage capability. In areas of higher exposure, the use of sealant in the interior and an insulation material that can readily drain and dry is preferred. When exterior perimeter insulation is used, space should always be provided for drainage and drying between the insulation and the cladding.

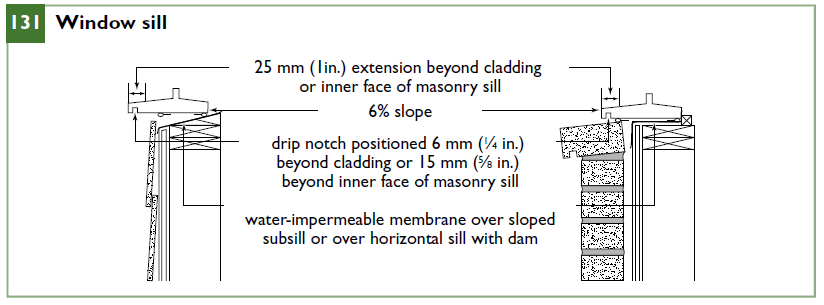

Provide continuity of the water shedding surface at the first plane of protection by using sealant and trim at the window perimeter. A drip edge is recommended at the sill because it causes water to drip free of the cladding below, reducing the probability of water running back into the wall assembly and the staining created by concentrated water run-off.

Figure 131 shows two drip edge arrangements for a window sill. Attach windows securely to framing members (Figure 132).

Figure 131

Figure 132

Energy-efficient windows that come with double or preferably triple glazing and low-conductivity frames can provide significant energy savings. They should be installed with spray foam or sealant around the perimeter between the frame and the rough opening to reduce air leakage and water ingress. There should also be flexible membrane sub-sill flashing across the rough sill and extending at least 100 mm (4 in.) up the sides of the rough opening.

The sill flashing should be sloped towards the exterior to prevent bulk water from entering the wall (Figure 11). Position the window in the rough opening so that the insulated glazing is in line with the wall insulation. In thick walls, the window should be placed close enough to the interior to allow heated room air to ‘wash’ the inner surface of the glass to prevent condensation and inwards from the exterior wall surface so that it is protected from rain and snow, yet near enough to the exterior so that flashings and membranes are not excessively large.

Source : Canada Mortgage and Housing Corporation (CMHC)